Surface Finishing

Surface Finishing

Surface finishing processes may be employed to: improve appearance, adhesion or wettability, solderability, corrosion resistance, tarnish resistance, chemical resistance, wear resistance, hardness, modify electrical conductivity and other surface flaws, and control the surface friction.

At NICA we offer solutions in surface finishing and treatment for PCB, sanitary ware, smart phone and computer parts manufacturing, photovoltaic, automotive, GMF , IC substrate and aerospace industries. NICA provides turn key solutions for our clients from initial system development phase to managing their system lifecycle ensuring our client’s success in their operations.

We fully understand that each client has its own unique requirements and with our in depth knowledge of the applications and industries, our clients can be assured of professional and successful customized surface finishing solutions

| TECHNOLOGIES | |||

|---|---|---|---|

In our production solution for this market, we’ve the following technologies to offer |

|||

| Surface And Wet Process For PCB | Plating On Plastics (POP) | Anodization Treatments | Barrel Plating |

| Reel-to-Reel Plating | Hard Chrome Plating | Nickel-Chrome Plating | Electroless Nickel Immersion Gold (ENIG) |

| Electroless Sn, Ni/Pb/Au Plating Equipment | |||

PANEL and PATTERN plating as well as automatic panel loading and collecting devices for processing thin panels with micro vias, We take special measures to do the loading and bubble removal in order to improve yields.

The equipment can be designed in accordance with customer’s requirement so as to process ordinary metal, aluminum material or PCB. Our technical know how enables one to acquire stable quality and lengthen the replenish life of electroless Nickel solution.

We supply a series of PCB Wet-Process Equipments ranging from Desmear/PTH, High Speed VCP and Roll to Roll systems for HDI, FPC and IC substrates.

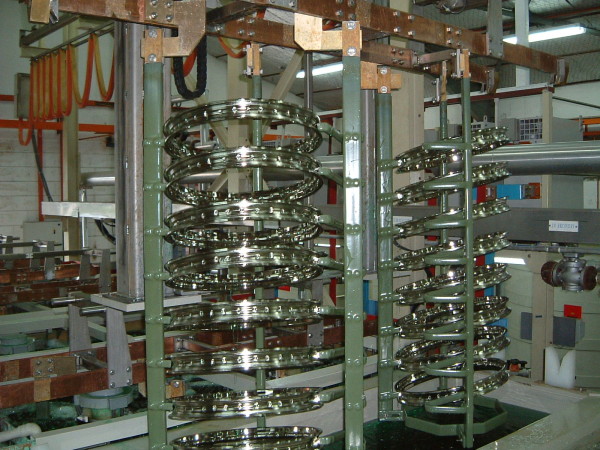

Our equipment is suitable for plating auto-parts, faucets, car emblems , cell phone case and other plastic products. We provide different transportation systems such as gate type , side-arm type or annular type to best suit your needs.

We provide Aluminium/Magnesium anode systems suitable for customized anodization treatments for cell phone casing, computer casing, auto-parts, aviation and a wide range of applicable industries.

Constant Current Density Anodization

Today, the modern anodizer is faced with challenges never before considered. Many advances technologies have pushed many of the anodizers into the “high-tech” world. Some of the advances, properly implemented, can save the anodizer a lot of time and money. The very important revolution in anodize oxidation industry is to apply constant current density in anodizing.

| Items | Constant Voltage | Constant Current Density |

|---|---|---|

| Theory | Control the car by accelerator pedal | Control the car by cruise control |

| Oxide Thicknass Tolerance | Big | Small |

| Oxide Film Hall | Big | Small |

| Oxidize Time | Long | Short |

| Seal Stability | Not so good | Extremely Good |

| Dye Stability | Not so good | Extremely Good |

Do you want to get

Smaller oxide Thickness Tolerance

Smaller Oxide Film Hole

Shorter Oxidize Time

Better Seal Stability & Dye Stability ?

This is not a dream!

Applying PAS II~III to get scientific method and more reliable anodize oxidizing result!

A variety of precise barrels with diameter of perforation as small as 1mm are available. With our specially designed barrel cylinder and barrel cover, a work of 0.2mm in thickness won’t be stuck into seam between the barrel cylinder and the barrel cover. This feature allows our barrel plating equipment used in plating precision electronic components. Additionally, higher plating efficiency, better quality and shorter plating time can be achieved with 40% of perforation rate.

In addition our sanitary ware plating equipment has cooperated with worldwide big sanitary group for new product and advanced products development, producing for a long time. We are well experienced in Copper and Zinc products.

Reel-to-reel plating is suitable for plating parts come in strips such as terminals and lead frames. The system consists of loading buffer, plating and reeling stages. For semiconductor application, a high pressure desmear unit that removes plastic grounds may be well fitted.

Hard chrome plating provides excellent abrasion, wear and corrosion properties, and it is able to yield great hardiness value. These characteristics are applicable for critical engineering applications, including machine tool cutting surfaces, cylinder bores, strut rods, crankshafts, hydraulic shafts and pistons.

Nickel-chrome plating is the most common decorative and functional metal plating technique in which a thin layer of chrome is plated over a layer or multiple layers of nickel plating. Due to its excellent corrosion and wear resistances, nickel chrome plating is widely used in automotive parts, tools, and kitchen utensils.

Electroless nickel immersion gold (ENIG) is a type of surface plating that consists of an electroless nickel plating covered with a thin layer of immersion gold which prevents the nickel layer from oxidation. Its excellent surface planarity makes ENIG ideal for fine pitch surface mount technology (SMT).

Electroless Sn, Ni/Pb/Au Plating can be customised for plating metal or PCB in accordance with customers’ requirements. Our equipment ensures stable quality and prolongs replenishing interval of electroless nickel solution.

Website Design by iClick Media